There are a lot of ways that businesses can invest in eco-friendly and recycled materials to lower their carbon footprint. One option is to use FIBCs.

Flexible intermediate bulk container (FIBC) also known as jumbo, bulk bag, super sack or big bag is an industrial container designed for storing and transporting dry, flowable products. One of the leading industry experts, FPS, offers a wide range of FIBC solutions, tailored to meet the diverse needs of industrial packaging. The FIBCs are made to ensure safe and efficient handling of chemicals, food, agricultural produce and other dry goods. Each of the super sacks is designed with durability and safety in mind.

FIBCs are considered eco-friendly since they are easy to reuse and recycle. They are made of a type of polypropylene that is very durable, which means it can be reused. This helps lower the amount of waste from packaging materials. Additionally, they are very lightweight which translates to lower carbon emissions during transportation. They also carry larger shipments, which helps lower the number of trips taken. Their recyclable nature makes them great for businesses trying to go green.

What are FIBCs made of?

FIBCs are often made of woven strands of oriented polypropylene, either coated or uncoated. normally measuring around 45-48 inches (114–122 cm) in diameter. They vary in height from 100 to 200 cm (39 to 79 inches). The containers are built to handle demanding conditions, offering reliable storage for materials with capacities up to 1,000 kg (about 2204.62 lb.). However, larger units are stored even more. An FIBC designed to transport one metric ton (0.98 long tons; 1.1 short tons) of material will itself only weigh 5–7 lb. (2.3–3.2 kg).

Types of FIBC Bags

FPS offers four types of super sacks (A, B, C, and D) to accommodate various materials and safety requirements: The variations when looking or super sacks for sale depends on several factors such as:

1. Product Type: Different materials require different types of FIBC for transportation or storage. These could be hazardous or non-hazardous materials.

2. Load Capacity: FIBCs handle weights between 500 and 2000 kg (about 4409.24 lb.). Selecting the correct capacity ensures safety during transportation and storage.

3. Safety Concerns (Electrostatic Properties): This is crucial for the safety of materials being transported. Type C and D bags are the best for storing and transporting hazardous or explosive materials.

Type A FIBC Bags (No Electrostatic Protection)

Made of woven polypropylene (woven PP) and other non-conductive fabrics, static electricity is generated as materials rub against the inside surface of the bag as they are filled and emptied. No static protection is provided by Type A FIBCs. These bags are used to safely transport non-flammable products and should not be used when transporting flammable or hazardous materials or in hazardous locations.

Type B FIBC Bagsnductive Bags)

Also known as conductive bulk bags, they are designed to handle flammable or combustible materials. These bags are made from non-conductive polypropylene fabric interwoven with conductive threads. These threads must be electronically interconnected and connected to a designated earth during filling or discharge. Type C bags are suitable in industries where explosions pose a concern.

Type D Bulk Bags (Static Dissipative Bags)

Type D bulk bags are made from fabric that includes static dissipative properties. They safely dissipate static electricity without relying on grounding. These super sacks are used for transporting flammable powders or when flammable gases or vapors are present. Type D bags are commonly used in environments where grounding is not possible, such as the food and chemical industries.

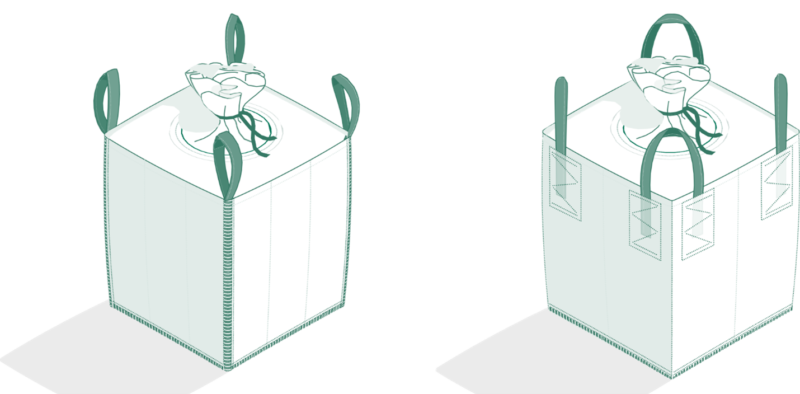

Standard FIBCs loop design & fabrics

When searching for super sacks for sale, considering customizable solutions to meet your specific needs is important. FPS offers various loop designs, including corner and cross-corner loops, and produces FIBCs in different sizes to match any operational requirements.

1. Corner loop

2. Cross-corner loop

Using FIBCs in your logistics operations is a wise choice for businesses looking to minimize waste, lower expenses, and support sustainability. Their reusable design, compact storage, and wide range of uses make FIBCs an environmentally friendly option that meets today’s contemporary green standards.

Environment10 months ago

Environment10 months agoAre Polymer Banknotes: an Eco-Friendly Trend or a Groundswell?

Environment12 months ago

Environment12 months agoEco-Friendly Home Improvements: Top 7 Upgrades for 2025

Features9 months ago

Features9 months agoEco-Friendly Cryptocurrencies: Sustainable Investment Choices

Features10 months ago

Features10 months agoEco-Friendly Crypto Traders Must Find the Right Exchange