Features

What Green Businesses Can Expect From CNC Machining In The Future

Green businesses are looking for more sustainable manufacturing solutions. There are a number of ways that manufacturing can be changed to produce a lower carbon footprint.

One of the changes people are considering is CNC machining. This is a good way to lower emissions and help make products more sustainably.

One of the biggest reasons that CNC machining is greener is that it can be done electronically. Customers can send electronic files to the factories, which means that they don’t have to travel to the site. This is an underrecognized greener alternative, because it reduces carbon emissions from driving.

CNC Machining is the Key to Sustainability in 2020

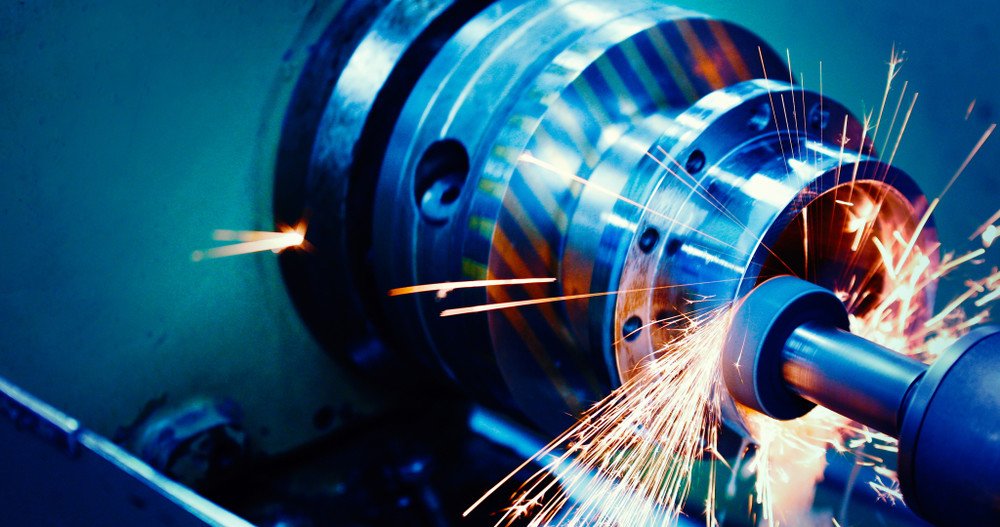

Just like everything else that surrounds us, modern manufacturing and production are rapidly changing. One particular item driving this growth is the CNC machine. First introduced in the 1940s, these Computer Numerical Control (CNC) machines changed the manufacturing game forever. They make it possible to scale any given manufacturing process without losing quality and accuracy along the way. Over time, with the widespread use of computers, CNC machining has become an essential part of the manufacturing sector.

One of the many benefits of CNC machines is improved efficiency. Smart green companies are using it to lower their carbon footprint to a significant degree. Science Direct published the summary of a study from Finland, which identified various ways that CNC machining lowers emissions. One of the biggest reasons CNC machining lowers emissions is by reducing transportation, but it also reduces material waste and machining time as well. This means that there is less of a carbon footprint with running machines longer than necessary or removing large amounts of waste.

Since technology has come a long way, nowadays, CNC machines rely on Computer-Aided Design (CAD) files to create prototype parts. With every part of the process controlled by a computer, these parts come as extraordinarily technical and highly automated products. To achieve such precise level of control, old industrial equipment such as routers, drills, and lathes are driven by unique computer programs, which make CNC machining stand out. As it simplifies the whole manufacturing process, it is widely used in many different industries.

There have been a number of changes with CNC products in recent years. There are a lot of changes in the CNC industry, which green living experts should be aware of.

Cheaper CNC Services

CNC machining is getting cheaper and more affordable than ever. Altogether with the machines, it’s becoming more economical to commission a company that offers CNC services to do any machining. Prototyping companies can buy these machines at a fraction of the cost they used to have. Furthermore, the barrier of entry into the CNC machining industry is lower than ever. Because of this, serious outsourcing companies now offer a diverse range of services, including prototype manufacturing and prototype machining.

Internet Of Things

It’s nothing new that most of the planning and organization of our lives is done on devices. So the question here is, why can’t be the same done in factories? There are many changes, caused by the the Internet of Things (IoT). This new technology is providing automation in incredible ways. IoT facilitates communication between machines within a given network. This encourages collaboration, which leads to the development of a higher-quality product.

Machines are also connected to computers or mobile devices, so some of these companies are offering their services online. CAD files can be transmitted electronically, which enables them to work on the project. This stuff is better yet in CNC machining, but you can also send designs for injection molding services and rapid machining.

Fear of Unemployment

There are a lot of concerns about automation these days. One of the biggest concerns is that it will displace workers.

At the same time, automation can help create new jobs too. Companies that offer CNC machining services will need maintenance, upgrades, and updates for their machinery. Technicians will always be around to troubleshoot and take care of CNC machines. Also, programmers with machine learning skills will be in higher demand as the software in these machines will have to be coded by such.

Smaller Devices

Not that long ago, CNC machines were huge and pretty dangerous to work on. As the technology evolves, so has the manufacturing process of these machines. Nowadays, it’s pretty easy to find prototype molding machines that can fit in a single room or even less. CNC machines have become smaller and more compact. Since they can now interact with each other and work together, companies are going with many smaller portable devices instead of big, immobile machines.

Take 3D printers as an example. Even though many people don’t consider them as part of the CNC machining family, they are and can fit in your room.

Once the merger amongst IoT and CNC machining is done, machines will be able to work indefinitely. As companies that offer rapid machining can’t afford to have any downtime, engineers are tirelessly working to improve the reliability of the machines. As the demand for CNC-machinery-made products increases, so does the need for CNC machines that operate at optimum levels.

As numerous companies turn to automated systems, coders and developers will have to make the control systems as intuitive as possible. This implies that they will need to simplify the user interface of the machinery and make them more user-friendly.

Product Quality Improvement

As companies strive to produce the most excellent products possible, CNC machines will only get better with time. Competitive companies that offer CNC services are continuously working on tightening their tolerances and quality control systems. They are offering to produce orders of any quantity, using a wide range of materials selection, at affordable prices with the highest quality possible.

Better Tech Support And Further Investments

With companies adopting different technologies of the modern era, the world of CNC machining is continuously changing for the better. CNC machinery companies extensively engage tech support representatives to improve their tech support offerings of the machines.

Companies that haven’t invested in CNC machinery will experience hard times trying to catch up with their competition. As robots and machines work 24 hours a day, companies that adopted the CNC machining process could quickly decimate the market share of the companies that are still questioning whether to jump on the bandwagon.

The Future Is Now

Services such as rapid prototyping in the industry are already fully automated, and companies that don’t embrace this automation risk being left behind. If you are into staying competitive on the market and cutting manufacturing costs, at least explore the idea of automating the process of manufacturing in your company. Even though the changes towards an automated industry do cost a lot of money, the upside of the whole switch is so vast that companies end up losing money if they don’t take the path of CNC machining.

CNC Machining Is A Green Alternative To Traditional Manufacturing

There are many ways that companies can take greener initiatives. One way to lower emissions is by using CNC machining. With much more to come that we can’t even envision from today’s perspective, look ahead and make sure your company is staying competitive. The future is now!