Features

Smart Filtration Is Reshaping Green Manufacturing Practices

Smart filtration is becoming a big part of greener manufacturing, especially as more factories look to reclaim and reuse materials instead of discarding them. Filters that separate oils, metals, and chemicals can extend the life of equipment while cutting down on waste. It ain’t always perfect, but the goal is to use what’s already there instead of pulling in more resources. According to SNS Insider, the sustainable manufacturing market was valued at $199.66 billion in 2023, and it’s projected to more than double by 2032.

The process of reusing filtered materials helps lower energy use and reduce the need for virgin inputs. When systems are set up to clean and recirculate water or air, it puts less pressure on the environment and saves money in the long run. People don’t always see the behind-the-scenes stuff, but it matters just the same. A 2022 report by the Manufacturing Leadership Council found that 58% of manufacturers are actively working sustainability into their process.

Reducing what gets dumped or wasted is another major benefit. Smart filtration helps trap harmful byproducts before they can get released into the air or water supply. Sometimes it don’t catch everything, but it’s way better than letting toxic materials run free. This kind of waste control helps companies meet local environmental standards while building better habits around how they operate day to day.

The market growth is no accident—companies are responding to global pressure and internal demand for cleaner practices. The global sustainable manufacturing market is expected to hit $430.64 billion by 2032, showing how quickly this shift is happening. It’s moving fast even if not everyone’s talking about it. Smart filtration might seem like a small part of the process, but it supports big changes without needing a full overhaul.

Manufacturers at the minute are under a lot of pressure from the government and intergovernmental agencies to change the way they work. Even food manufacturers are finding ways to be greener. However, as new regulations and voluntary standards continue to emerge, manufacturers must reduce the amount of waste they produce in order to make their processes more energy efficient and, as a business, minimise their carbon footprint.

But how can manufacturers do this?

Smart filtration systems can help manufacturers meet these regulations by improving process filtration to do more with less. Let’s take a deeper dive.

What is Smart Filtration?

Smart filtration refers to advanced, adaptive filtration systems that use automation, data integration, and real-time optimisation to optimise processes. Smart water filter systems continuously monitor water quality, flow rates, and system performance and adjust operations to what is needed.

How Does Filtration Support Sustainability?

Preserves Product Quality

Contaminants and other harmful particulates can accumulate during the manufacturing process. If these contaminants get into the product, it can affect the quality of the product which, in turn, leads to more waste.

Especially in industries like food and beverage or pharmaceuticals, there is a big risk of contamination from bacteria, sediment, or mould spores which can compromise the safety and quality of the final product. Filters remove these substances to help create consistent, high-quality products.

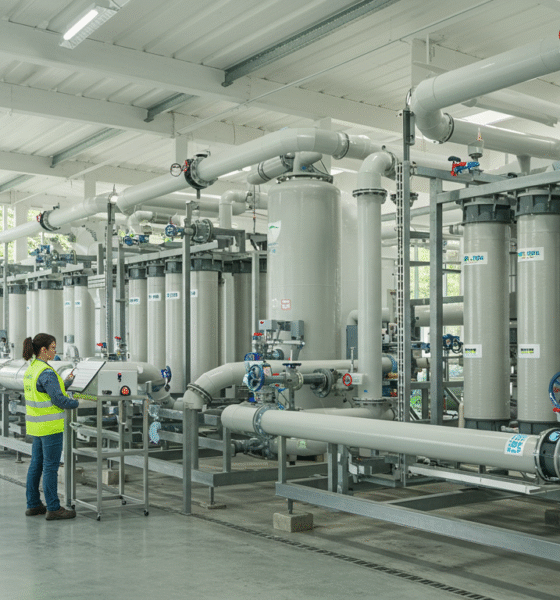

Conserve and Recover Resources

Manufacturing generates billions of tons of waste every year and consumes huge amounts of water every single day. Smart filtration systems play a key role in reducing this impact by enabling manufacturers to recover and reuse these raw materials.

Filters improve water quality, and reduce reliance on freshwater sources and chemical treatments, all the while supporting sustainable practices like wastewater recycling that lead to lower costs and environmental impact.

Improve Process Efficiency

During manufacturing, poorly maintained machinery can use more energy to produce the same output, and is more likely to break down. Smart filtration systems can remove unwanted particles from fluids to prevent equipment from failing, minimise friction, and reduce drops in pressure. This can ensure manufacturing processes are energy efficient, leading to increased production rates, minimal downtime, and a reduced carbon footprint.

Convert Waste to Energy

By switching to smart filtration, manufacturers can turn waste into energy through processes like anaerobic digestion and pyrolysis. These processes produce biofuels that reduce the dependence on fossil fuels, contributing to a growing circular economy.

How to Implement Smart Filtration

While most manufacturers believe in integrating new technologies, many get stuck in the ‘pilot phase’ which means they fail to ever fully roll the transformation out. However, there are steps you can take in order to complete the transformation.

Ensure Your Infrastructure Supports Change

Smart manufacturing relies on strong network infrastructures. Without it, smart filters can produce inaccurate data.

Think Big

Rather than focusing on small changes which can limit returns on smart manufacturing investments, you can unlock bigger value with more impactful results by simply thinking big with your transformation.

Prepare for the Long Haul

Transformations are a long-term investment, and immediate returns might be limited. However, laying the right foundations can allow for a future-proof process.

Takeaway

Smart filtration plays a big role in helping manufacturers reduce their environmental impact by preserving quality, reducing waste, and improving efficiency. Green manufacturing is the future, so make sure you’re taking the right steps towards a meaningful sustainable transformation.

Environment12 months ago

Environment12 months agoAre Polymer Banknotes: an Eco-Friendly Trend or a Groundswell?

Features11 months ago

Features11 months agoEco-Friendly Cryptocurrencies: Sustainable Investment Choices

Features12 months ago

Features12 months agoEco-Friendly Crypto Traders Must Find the Right Exchange

Energy11 months ago

Energy11 months agoThe Growing Role of Solar Panels in Ireland’s Energy Future